In the case of surface peripheral plunge grinding, there is a possibility of changing the material removal rate by means of both workpiece speed and the depth of cut. However, one can also alter both variables in an inverse fashion such that Q’w remains constant.

Fig. 6-110 shows how the methodological variants of deep feed grinding (large depth of cut ae, low workpiece speed vw) and pendulum grinding (small depth of cut ae, high workpiece speed vw) affect process parameters and the output.

The low workpiece speeds involved in deep feed grinding, also known as creep feed grinding, in conjunction with the large depth of cut lead to long, thin chips and a large contact arc. The chip volume accrued per cutting edge is larger that in pendulum grinding and cooling lubricant supply to the machining location is more difficult. The deep feed grinding wheel must therefore exhibit a sufficiently large chip space. For the methodological variants of deep feed and pendulum grinding, specific grinding wheels have been developed that take into account the varying kinematic conditions.

|

A comparison of methods when using a single grinding wheel should therefore not cover the entire range from deep feed to pendulum grinding, but rather be attuned to the area of application dictated by the respective grinding wheel.

If grinding wheels suitable for pendulum grinding are also used for creep feed grinding and vice versa, varying curve shapes result depending on the variables. For example, wear increases if a grinding wheel made for pendulum grinding is used in creep feed grinding conditions, while it decreases when a grinding wheel made for creep feed grinding is used.

Furthermore, one must take it into consideration that the material removal rate at which the ae-vw combination results also influences the curve shapes. If the depths of cut and workpiece speed are varied at a low specific material removal rate, the differences between deep feed and pendulum grinding are generally smaller than when there is a ae-vw combination with a high material removal rate.

The increase in cutting forces along with the depth of cut at a constant material removal rate can be explained by the following mechanisms. With a larger depth of cut and lower workpiece speed, the chip cross-sectional area is diminished. At the same time, the actual cutting edge number increases because of the larger contact length, although the kinematic cutting edge number is reduced as a result of the lower workpiece speed and the resultantly lower chip thickness [KASS69, WERN71]. The reduction of the chip cross-sectional area is overcompensated by the increase in actual cutting edges such that the cutting force as a whole rises.

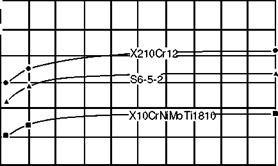

In accordance with the increase in cutting force, the cutting power Pc also increases with the depth of cut (Fig. 6-111).

A 100 M7 B

Grinding

parameters

Vc = 60 m/s

Q’w = 10 mm3/mms

Cooling lubricant

Oil

250 100 50 33,3 25 20 16,7 14,3 12,5 mm/s 10

Fig. 6-111. Power requirements as a function of the depth of cut and workpiece speed when grinding various materials

When a grinding wheel for pendulum grinding is used (Fig. 6-112), the edge wear area Ase increases with the depth of cut [KOEN71]. Other investigations in creep feed grinding utilising a grinding wheel suited to this process have shown that edge wear decreases again after a maximum value is exceeded, resulting in more favourable vales than in pendulum grinding [SALJ77].

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

A 100 P B

A 100 P B

Grinding

parameters

vc= 60 m/s Q’w = 10 mm3/mms Vw= 1000 mm3/mm Cooling lubricant Oil

|

Workpiece speed vw

Fig. 6-113. Surface quality as a function of the depth of cut and workpiece speed for various grinding wheel specifications

Disparities in wear can be explained with the help of two mechanisms that influence pendulum and creep feed grinding differently. On the one hand, in pendulum grinding the number of cuts is larger so that an increase in wear is especially apparent when soft creep feed discs are used. On the other hand, temperature and stress duration both increase during creep feed grinding, becoming dominant cases of wear. The longer action time of the heat source during creep feed grinding also contributes to this. Form and dimensional faults exhibit parallel behaviour to the

parameters that cause them, so there is a relation to both the cutting forces as well as to wear.

Fig. 6-113 shows the relation of the average surface roughness Ra to the depth of cut and workpiece speed. Since chip thickness decreases degressively at constant specific material removal rates with increasing depths of cut, deep feed grinding can produce a better surface quality than pendulum grinding [KASS69, KOEN71, SALJ77, SPER70].