Higher wheel speeds allow higher infeed rates to be employed. Increasing wheel speed without increasing infeed rate reduces chip thickness as can be seen from Equation 19.30. In this case, roughness is reduced and grinding forces are reduced although specific energy is increased due to the size effect. The purpose of increasing wheel speed is to allow infeed rate to be increased, thus increasing production rate while maintaining quality levels and process efficiency.

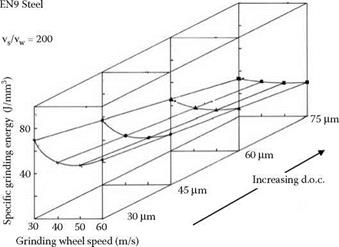

Within the stable range, increasing workspeed has a relatively small effect on the process. As workspeed is increased, specific energy is increased as may be deduced from Figure 19.23 and Figure 19.24.

At high workspeeds, the probability of chatter is increased, so there is effectively a maximum workspeed due to the chatter. These results are for a particular workpiece diameter. It is, therefore, necessary to undertake trials for the particular workpieces to be produced. Figure 19.20 shows the chatter limit can be increased by improved machine design to raise the principal resonant frequency.

At low workspeeds, the probability of thermal damage to the workpiece increases. The burn boundary can be moved outward by using a sharper abrasive to reduce the specific energy.

|

FIGURE 19.24 Specific energy with increasing depth of cut and wheel speed for constant vs/vw. |

TABLE 19.1

Depth of Cut, Feedrate, and Equivalent Chip

Thickness, dw = 50 mm Diameter

Depth of Cut Equivalent Chip

(^.m) Thickness (^.m) Infeed Rate/Workspeed

30 0.152 0.000386

45 0.224 0.000570

60 0.302 0.000770

75 0.379 0.000965