This refers to a range of products using wheels in the 5- to 25-mm-diameter range to grind extremely high volumes of components on dedicated grinders. Tolerances now become somewhat relaxed compared with those for fuel injection and fall in the 1 to 5 pm range.

The key to these machines, though, is cycle time, much of which is won or lost in nongrind time. For example, a 20-mm-diameter component with 0.2-mm radial stock can be rough ground at Q = 5 mm3/mm/s in 2.5 s. However, the total cycle time can vary from over 15 s on an old hydraulic/mechanical grinder to less than 7 s on a modern CNC grinder. The savings are in improved load/unload mechanisms, faster slide movements, gap elimination, optimized spark-out times, and ability to use CBN wheels (Table 18.3).

18.5.4 Machine Layout

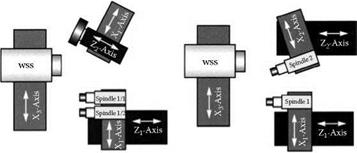

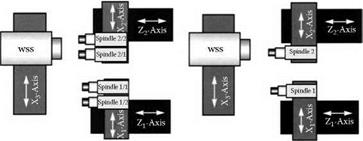

The machine design starts with the overall layout of the components. Since only a limited amount of travel is required, the X-axis and Z-axis are on independent slide systems as in the example from Bryant (Figure 18.19) [Koepfer 1995]. This allows all the moving components, wheelhead, and workhead close to the machine bed and ballscrews for improved stiffness and thermal stability. Most builders use hydrostatic slides for rigidity and speed (up to 40 m/min) or more recently linear magnetic slides, especially on the Z-axis with the need for high-speed oscillation.

18.5.5 Wheel Speeds

Wheel speeds with CBN of 30 to 60 m/s are now readily achievable with available spindles operating at 40,000 to 70,000 rpm with a good torque range. Higher speed spindles are available but these appear to lack the same rigidity, power, or durability. Most modern grinders will maintain a constant wheel velocity as the wheel gets smaller. It is important to check that there is available rpm/torque for the full life of the wheel size and abrasive type especially if planning to use both CBN and alox.

18.5.6 Work-Spindle Runout

Workhead spindle runout is held within the range 0.25 to 1.00 pm depending on part tolerances. Speeds can vary within the range of 500 rpm to 3500 rpm depending on the particular application.

|

|

|

FIGURE 18.19 Modular machine designs allow for different configurations of multiple grind operations (seats, bores, and faces). (From Bahmuller 1997. With permission.) |