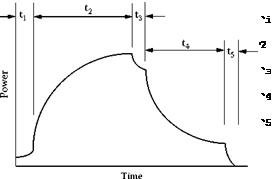

The grind cycle on a standard internal grinder consists of a series of fixed infeed rates and amounts, namely, a rapid approach, rough grind, finish grind (10 to 30 pm), spark-out, retract, and unload/load. Figure 18.9 graphs the programmed slide moves with time for one grind cycle.

|

|

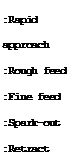

Figure 18.10 illustrates the associated grinding power. There is a rapid climb during roughing leveling off during the finish grind, then going through an exponential decay during spark-out. The spark-out time should ideally be three time constants after which no further material removal or improvement in finish will occur as the threshold force is reached. The graph shows an ideal situation for a part with zero runout entering the grind cycle. In reality, the part will typically have 50 to 100 pm runout and the smooth climb in power during roughing will have superimposed on it rapid oscillations with the frequency of the work rpm. The amplitude of this will reduce but can still often be seen during spark-out demonstrating the level of out-of-roundness still remaining in the part after grind.

In addition to a superimposed oscillation from runout, any excess stock will show up as a power spike during rapid infeed. Any such spike will be deleterious to wheel life.