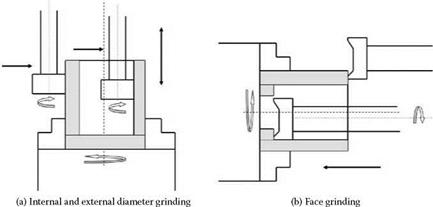

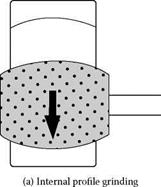

In the basic internal grinding process, the wheel is fed perpendicularly into the part usually accompanied by a short-stroke high oscillation along the axis of the wheel. The part is rotated in the opposite direction to the wheel (down grind) in virtually all applications except occasionally in finish grinding with large interrupted cuts if roundness is an issue. The basic internal grinding process is illustrated in Figure 18.4.

Internal grinding is a very weak system where the primary weakness is the wheel mount or quill. This can readily deflect during the grind leading to problems of taper and shape. The grinding conditions are driven first and foremost by the system stiffness and the level of normal grinding force. The key factors to consider are shown here.

|

|

|