17.2.1 Introduction

The last 25 years has seen a dramatic growth in the use of vitrified CBN at wheel speeds of 80 m/s up to as high as 200 m/s in certain key cylindrical applications. Three such applications, camshaft grinding, crankshaft grinding, and peel grinding, will be discussed to illustrate what the technology is and where it is likely to expand. In light of the limitations apparent when grinding with alox wheels at high speed, it is necessary to first review the current theories on heat generation and burn in grinding.

17.2.2 Energy and Temperatures in High-Speed Grinding

The starting point to the determination of grinding temperatures is the definition of uncut chip thickness

where

vs = wheel speed vw = workspeed ae = depth of cut de= equivalent wheel diameter C = active grit density r = grit cutting point shape factor

C and r are characteristics of the wheel and how it was dressed. They are usually treated as a single (Cr) factor. Uncut chip thickness is a reasonably reliable factor for predicting several grinding variables especially specific grinding energy e: 1

![]()

![]() hn

hn

cu

Since Cr is normally a constant for a given wheel/dress set of conditions some OEMs will use this factor to characterize a given wheel or compare performance from one wheel grade or type to another. Cr for a plated CBN, for example, is only 20% that of a typical vitrified CBN wheel. Similar predictions can be made for surface roughness, Rt, and force/grit, f.

h4/3

Rt surface roughnesss

force per grit

force per grit

|

Power can be predicted if typical values of specific energy for the particular wheel/material/setup are known. The second and more important step is to determine where the heat goes and what temperatures will be created.

There is an enormous amount of theoretical experimental work on heat and temperature models in grinding as introduced in Chapter 2. Much of this work has been refined and the important factors isolated [Rowe et al. 1996, Rowe and Jin 2001, Marinescu et al. 2004]. The maximum surface temperature depends on the grinding power (F’- vs), the grinding speeds, and material parameters. A mean grinding temperature when grinding with coolant is given by

where the thermal parameters in the equation that affect grinding temperature are described as follows.

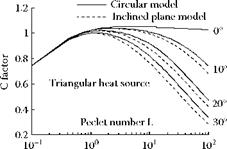

17.2.2.1 The C Factor

max

|

The value is approximately equal to 1 for conventional grinding. The value is reduced for deep grinding and at high workspeeds, that is, Peclet number, L. Rowe and Jin [2001] give charts of C values for maximum temperature Cmax (Figure 17.5) and for finish surface temperature (Figure 17.6).