The final method of grinding is a combination of infeed with traverse. This is a typical operation for long shafts and cylinders. An extreme form is roll grinding for the paper and steel industries. The nature of the wheel wear and the actual Q’ values become less well defined as the wheel is cutting on its leading edge. Since breakdown will be rapid with an alox wheel infeed amounts are kept at <15 pm on diameter and the wheel cross-fed up to one third (cross-feed one direction only)

|

|

|

|

or one fourth (cross-feed both directions) of its width per revolution of the workpiece. The cutting action is distributed over the feed width with two overlaps at size for finish.

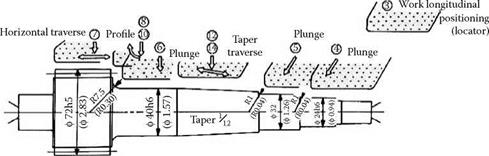

With modern CNC equipment, all the operations described above can be incorporated into grinding many surfaces in a single chucking as illustrated in Figure 17.4 [Okuma n. d.].