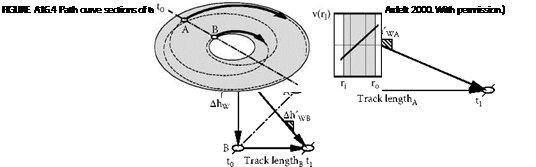

The previously shown description of path types during machining on double-wheel lapping and fine grinding machines reveals a very broad range of the rotational speed ratio. This theoretical analysis

|

1 A |

в |

||

|

Ahw = Constant Ah’w = f(ij) |

|

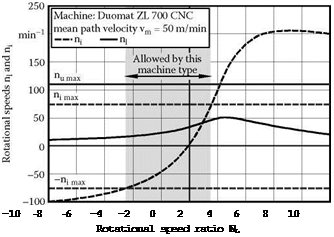

FIGURE A16.6 Necessary rotational speeds to achieve a mean path velocity of 50 m/min at different rotational speed ratios NL. (From Ardelt 1999. With permission.)

was carried out, irrespective of the rotational speeds that can actually be set on real machines. Most standard designs permit rotational speeds at the inner pin circle of 50 to 80% of the wheel speed. This means that a rotational speed ratio of 10 can only be reached with 5 to 8% of the maximum wheel speed. This minimum usage of the machine power considerably limits the settable path velocities. To illustrate this fact, for a machine of the type Duomat ZL 700, Figure A16.6 shows the rotational speeds that must be set at the inner pin circle and the lower grinding wheel to reach a mean path velocity of 50 m/min for all rotational speed ratios. The maximum rotational speeds possible are given by the horizontal lines. The perpendicular bar represents the range of settable rotational speed ratios, which is restricted in both directions by the inner pin circle [Uhlmann 1999].

|

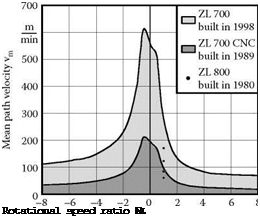

Due to the technological progress in driving technology on the one hand, and knowledge of lapping kinematics on the other, kinematic possibilities of machine systems are constantly expanded and improved. To illustrate this development, Figure A16.7 compares the kinematic possibilities of various generations of the machine family ZL by Stahli GmbH.

For the ZL 800 (built in 1980), the rotational speed ratio between inner pin circle and lower lapping wheel is set firmly by a gearing. Changing the poles at the driving motor serves to realize four different velocities. Freely selectable rotational speeds permit any rotational speed ratios for the design ZL 700 CNC (1989). For the path velocities needed for grinding the range of possible path types is strictly limited. Possible rotational speeds are considerably higher for the ZL 700 built in 1998. Here, both grinding wheels can be driven with up to nul = ±435 min-1, the inner pin circle with up to n = ± 268 min-1. These rotational speeds allow for mean path velocities vm of more than 600 m/min or 10 m/s.