Creep feed grinding with CBN can be divided quite definitively between plated CBN and vitrified CBN in terms of distinct machine conditions, coolant, and operating parameters.

|

TABLE 16.8

Example of Removal Rates in the Viper Process for Grinding Turbine Blade Root Forms

|

Pass

|

Wheel Speed

|

Table Speed

|

Depth of Cut

|

Dressing Depth

|

Q’w

|

|

(m/s)

|

(mm/min)

|

(mm)

|

(mm)

|

(mm3/mm/s)

|

|

1

|

35

|

1,000

|

1.0

|

0

|

16.7

|

|

2

|

35

|

1,000

|

0.5

|

0

|

8.3

|

|

3

|

35

|

1,000

|

0.2

|

0.2

|

3.3

|

|

4

|

35

|

1,000

|

0.1

|

0

|

1.7

|

|

5

|

35

|

1,000

|

0.05

|

0

|

0.8

|

|

6

|

35

|

1,000

|

0.02

|

0

|

0.3

|

|

|

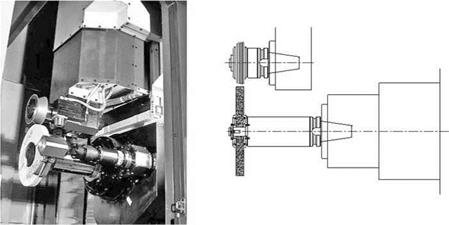

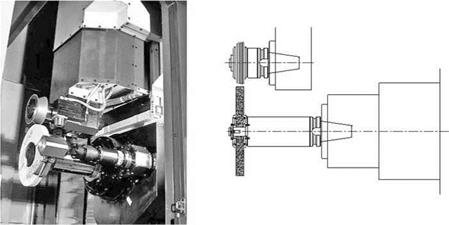

FIGURE 16.18 Makino machining center equipped with CDCF capability on quick-change HSK adaptors.

|

|

|

|

|

|

|

|

|

|

|

|

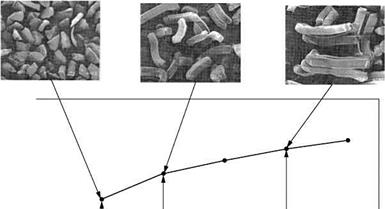

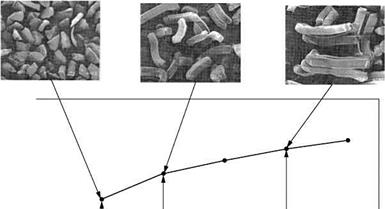

FIGURE 16.19 Large grain aspect ratios of SG and TG wheels.

|

|

![]()