Figure 15.56 shows a traverse diamond roll unit with a small double-barrel stepper motor infeed and a dc motor cross-slide and DFW-HTG spindle. This carrier is designed for traverse dressing of CBN and engineered ceramic wheels.

15.18.9 Plunge-Roll Infeed System for a Creep-Feed Grinder

Figure 15.57 shows a plunge roll infeed system for a Brown & Sharpe (Jones & Shipman) 1236 Hi-Tech creep feed grinder. The dresser is mounted over the wheel on the spindle head. The unit has a servomotor-driven triple-barrel infeed and electric belt-driven spindle assembly. It is equipped with TG angular contact bearing spindle arrangement.

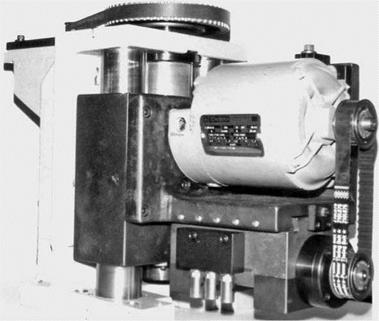

15.18.10 Servomotor Infeed and Double-Barrel Carrier Dresser

Figure 15.58 shows a rebuilt Cincinnati 220-8 centerless grinder with a servomotor infeed and double-barrel carrier dresser unit. The spindle has an 8-in.-wide roll capacity.

|

|

|

|

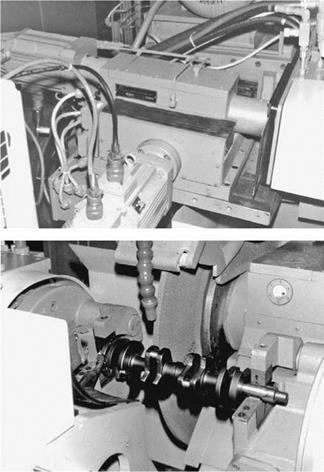

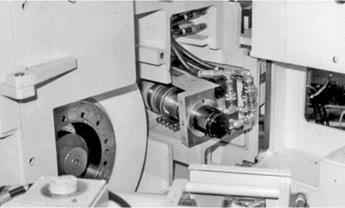

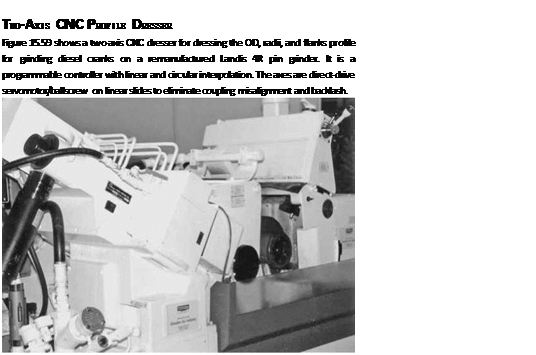

FIGURE 15.59 Pictures of a Landis 4R crank grinder retrofitted with a two-axis CNC dresser for radius profiling. |

Finally, Figure 15.60 and Figure 15.61 provide illustrations of plunge roll dresser spindles in situ on two typical grinding applications.

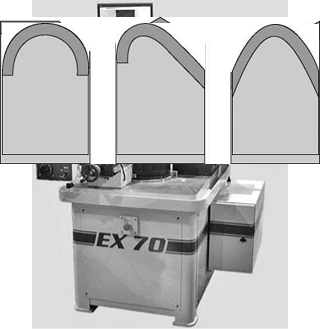

Generation of radii for the bearing industry is still often a problem using circular interpolation of two axes due to the limitations in encoder/ballscrew/control resolution. In many cases, the smoothest radial form is still generated by swiveling about a fixed-radius point. Most grinders in the field are equipped with single-point devices dressing alox or SG-type abrasive wheels, but Nevue [1993] demonstrated these could be readily retrofitted to small rotary devices for dressing CBN wheels.

For the most complex forms, especially in the gear industry, companies such as Normac (Arden, NC) have specialized in compact multiaxis units with accompanying software that can generate and interpolate gear tooth profiles direct from print dimensions. The dresser can be either mounted on the grinder or the wheels dressed offline on a separate machine (Figure 15.62). Offline dressing is common in the tool, thread, and gear-grinding industries. The equipment provided for this range from manual grinders, such as the Junker ARJ 250 example in Figure 15.63, which is designed to generate chamfers, bevels, radii, and other simple shapes, to fully programmable rotary dresser

|

|

|

|

|

FIGURE 15.63 ARJ 250 offline dresser. (Courtesy of Max Engineering, Howell, MI. With permission.)

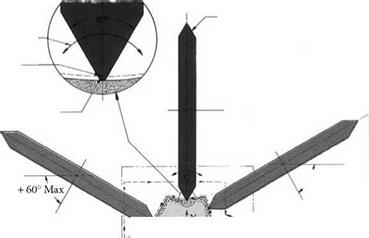

systems with control of X, Y, and C axes in order to maintain the dresser perpendicular to the wheel face for very complex profiles (Figure 15.64) [Orion 1993]. Again, software development is the most critical factor in this technology especially where interpolation of involute forms is involved [Kelly and Smith 1993].

Cutter pivots about C-axis

![]()

![]()

C-axis

C-axis

|

FIGURE 15.64 Orion engineering dresser [Division of Wendt Boart (with permission)] and profiling method.