|

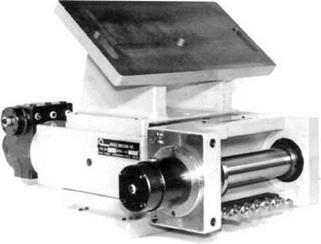

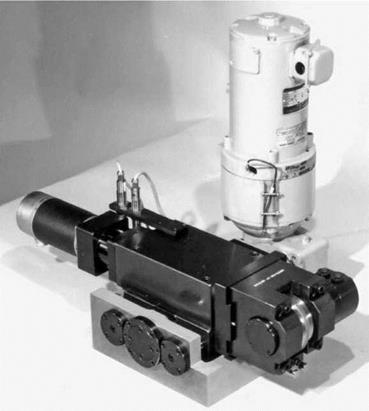

Figure 15.52 shows a double-barrel infeed carrier with hydraulic-mechanical compensator for plunge form dressing used on a Cincinnati 480 30° plunge centerless grinder. It replaced a hydrostatic single-point dresser unit and was equipped with a DFW-HHD heavy-duty hydraulic spindle.

|

|

FIGURE 15.52 Hydraulic-mechanical compensator plunge infeed system for centerless grinder. |

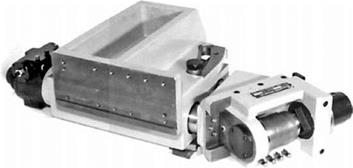

15.18.6 Triple-Barrel Infeed Carrier with Hydraulic-Mechanical Compensator

Figure 15.53 shows a triple-barrel infeed carrier for use on large centerless and multiwheel grinders. Custom designs can take up to 20 wide diamond roll assemblies. Note the series of coolant nozzles plumbed through the housing common to all the systems described.

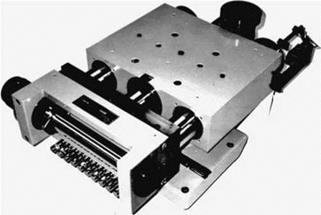

15.18.7 Stepping Motor Carrier

Figure 15.54 shows a stepping motor and ballscrew infeed compensated double-barrel carrier designed for the SGE-195 bearing grinder. It is equipped with a DFW-HC spindle for quick diamond roll changes.

|

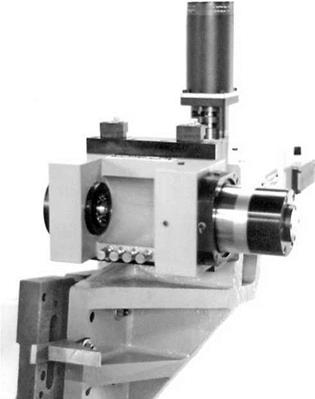

Figure 15.55 shows a stepping motor and ballscrew infeed-compensation double-barrel carrier suitable for a cylindrical grinder. The carrier is equipped with a DFW-HHD hydraulic spindle.

|

15.18.8 Stepping Motor Carrier for a Cylindrical Grinder

|

|

|

|

FIGURE 15.56 Two-axis combination stepper/dc motor traverse dressing system. |