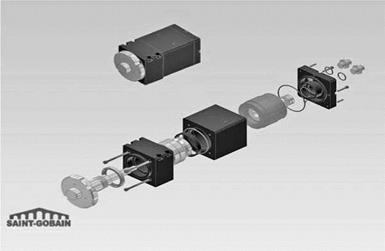

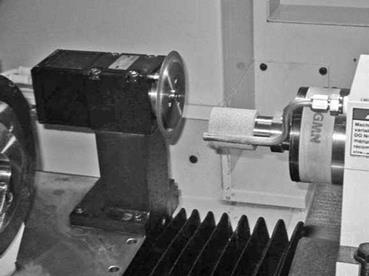

The key to any infeed system is high stiffness and damping, repeatability, and ease of maintenance. The units described below (Courtesy Wheel Dressing Division of Saint-Gobain Abrasives) have proven effective over numerous years in the field. There are a variety of designs combining dresser spindle units and infeed systems varying according to the application and particular features required for the particular application. The following range is described in chronological order from older hydraulic-mechanical compensator designs through dc stepper motors to direct- drive ac servos.

|

|

|

|

|

|

FIGURE 15.48 Single-barrel hydraulic-driven infeed system. |