The classic electric, belt-driven dresser shown in Figure 15.43 has an ABEC 7 ball bearing arrangement for table-mounted surface grinders such as creep feed. Air-oil mist porting is required to the bearings while custom porting is provided for dressing. A proximity sensor is often placed on the pulley to confirm spindle rotation. The spindle design can handle up to a 375-mm roll assembly at a fixed speed of up to 3,600 rpm with speed adjustment through changes to the pulley ratio. For the latest grinders with high wheel spindle power and coolant delivery systems the standard electric motor has been replaced by custom ac servo or dc servo motors for variable speed control and better motor sealing as shown in Figure 15.44.

|

|

|

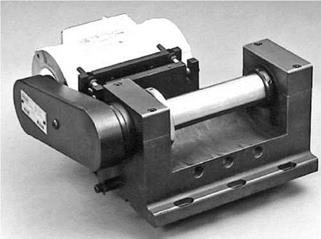

FIGURE 15.45 DFW VF45 ac servo HF electric traverse dresser spindle. |

15.17.10 DFW-VF44 AC Servo HF Spindle

The ac servo high-frequency motor shown in Figure 15.45 has a peak power of 0.375 kW at 5,500 rpm and a base frequency of 92 Hz. This style of dresser has been the standard for the United States for traverse dressing of vitrified CBN wheels for cylindrical grinding. It is now often fitted with an internal acoustic sensor for touch dressing.

15.17.11 DFS-VS8 DC Servo Variable-Speed Dresser

Figure 15.46 shows a dc brushless servo variable-speed dresser with constant torque and a peak power of 1.3 kW at 6,000 rpm. The spindle is supported on three sets of angular contact bearings including asset for outboard support. The 125-mm-diameter diamond roll has a 35-mm wheel width capacity. It is targeted at heavy-duty traverse applications and form plunge applications with narrow CBN and engineered ceramic seeded gel (SG) wheels. Figure 15.47 shows the unit mounted in a grinding machine for a dressing operation on an SG wheel.