Electric motors can be subdivided into three categories: traditional ac motors, ac servomotors with high — frequency drives popular since the early 1990s, and most recently dc brushless servomotors with high — frequency drives. The trend in these motors is to go to higher and higher power densities so as to be as compact as possible and, hence, give the maximum flexibility both to be fitted into smaller grinder footprints and to provide the additional power required for creep feed and vitrified CBN dressing.

There are numerous advantages to electric drives including the ability to run unidirectional (i. e., in an overrun situation where the grinding wheel tries to drive the dressing tool), a high power and power density, simple speed control, and cleanliness. Motor guarding is more of an issue to prevent coolant access to the windings but this is readily achieved with good rotating seals and/or positive air purging.

|

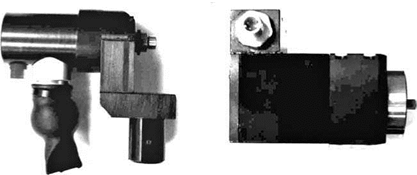

The enormous changes that have occurred in the last few years is exemplified in the photographs in Figure 15.36. These show two dressers from Wheel Dressing Inc. (Saint-Gobain Abrasives). The spindle to the left is a model ACI pneumatic spindle designed and in common use for over 25 years specifically for Heald internal grinders; it has a power rating of about 0.05 kW at 20,000 rpm. The spindle to the right is a dc servo brushless electric dresser with a peak power rating of 0.80 kW at 20,000 rpm. Both photographs are at the same magnification.

|

TABLE 15.2 Capacities of Common Dresser Spindle Designs rpm

|