|

|

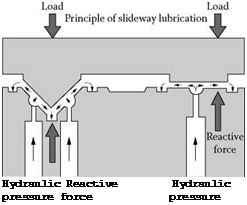

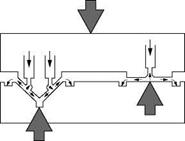

A simple double diaphragm valve design was developed by Rowe [1969, 1970] for hydrostatic slideways and for hydrostatic journal bearings. Designs of this type have been successfully implemented in various machine tools and give very high bearing stiffness.

|

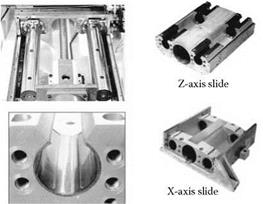

FIGURE 15.15 Bryant UL2 hydrostatic round slideway designs. |

The pressures at the individual pads can nowadays be controlled using ultrasensitive pressure membrane monitors and computer algorithms that regulate and optimize the flow and pressures. The method increases the stiffness and also reduces the oil demand of the system: this, in turn, reduces heat generation. The approach has been reported to be common on cylindrical, gear, and crankshaft grinders in Europe [Anon. 1999].