Slideways are traditionally made of cast-iron sliding on cast iron making use of the graphite present as lubricant or on porous brass, especially where gibs are applied. The brass is designed to wear preferentially while providing good lubrication.

The major limitation of these combinations is static friction or stick-slip that can create drive problems with servo errors. One way to reduce this is to use PTFE-based coatings with bronze fillers such as Turcite and Roulon. These have been used extensively, for example, by Koyo [n. d.], Kent [n. d.], Chevalier [2000], and Studer [n. d.]. Under load, the material has a static friction coefficient within 20% of its dynamic friction coefficient of 0.015 [Slocum 1992] (Figure 15.10 and Figure 15.11).

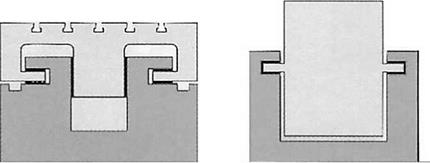

Alternative approaches include hydrostatic slideways and rolling element slideways; and the use of simple ball-bearing, or preloaded, nonrecirculating needle rollers as used by, for example, Fortuna [n. d.] in camlobe grinders in the 1980s and by Mitsui NC thread grinders at about the same time [THK n. d.]. These guideway systems may have less stiffness and damping than plain slideways while still having nonzero stick-slip but they are extremely compact. Rolling element slideways are discussed in more detail later after the discussion of hydrostatic slideways.

|

|