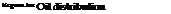

A variation on the Flat and Vee is the Double Vee slideway. This again depends on gravity for its preload and is self-compensating for wear. However, it can handle changes in the load position with much less yaw error. The major difficulty with this slideway design is in the manufacture, especially over any significant length. For this reason, it is most often used on short stroke axes such as the Z-axis on small manual and NC surface grinders, for example [Acer n. d.], or as the example in Figure 15.7 [Kent n. d.].

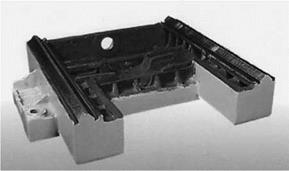

15.4.3 Dovetail Slideway

Other designs of slideway cross sections do not have the luxury of using gravity for preload and have to incorporate some form of constraint or box. The standard Tee-shaped slideway is shown in Figure 15.8 [Slocum 1992].

Preloading must now be achieved by gibs that are held in place by torqued setscrews. This leads to problems with backlash over time as the gibs wear. This particular design is more common in machining centers and mills where it can provide excellent damping at relatively low cost.

Plain constrained slideways offer probably the greatest stiffness and damping of any guideway system. It is perhaps not surprising that the Viking centerless grinder (Landis, Waynesboro, PA), which was designed specifically around maximizing its stiffness at 3 Mlbf/in., uses dovetail plain slideways.

|

![]()

![]()

![]()

![]()

![]()

![]()

Saddle (cast iron)

Saddle (cast iron)

Way wipers

|

|

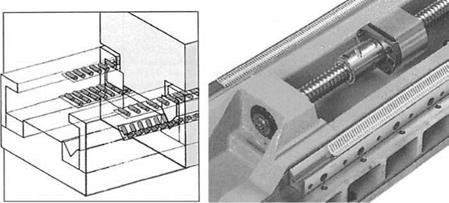

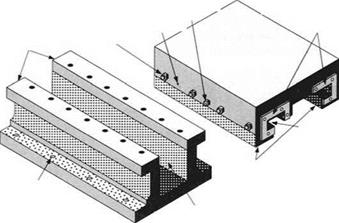

FIGURE 15.10 Example of Rolling Element slideway. (From Fortuna 1991. With permission.) |

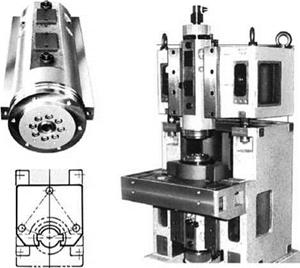

Koyo Machine makes use of a square slide version in order to obtain very high stiffness within a confined space for a slide to hold an upper vertical spindle for its superabrasive double-disc grinder [Koyo n. d.] (Figure 15.9). The sliding surface is hardened chrome while the slideway is coated with Turcite (see later).