|

Slideways traditionally refer to a range of linear sliding contact guideways based on square, T, or flat and V cross sections. In recent decades, the advent of NC and CNC machines has led to rolling element slideways for ease of positional control.

|

|

|

|

|

|

|

![]()

15.4.2 The Flat and Vee Way

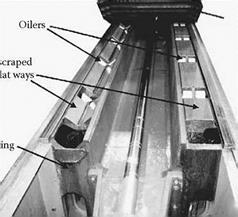

The simplest load-bearing arrangement is the “Flat and Vee” slideway. This uses gravity to preload the bearing configuration. It is considered by many machine tool builders as the optimum configuration for horizontal axes on large grinders under heavy, but even, downward loading. The path accuracy can be <1 pm and wear of the slide is self-compensating [Waldrich Siegen 1996]. Under uneven or changing load, it is prone to yaw errors. It is most commonly seen still on large surface grinders, for example, bed grinding or on cylindrical roll grinders that handle workpieces up to 10 tons or more. Figure 15.6 shows a photograph of the Flat and Vee way on a Favretto slideway grinder. The bearing surfaces are hand-scraped for good bearing contact and oil retention. The upper and lower surfaces are kept lubricated by oilers that consist of a series of rollers semisubmerged in small oil reservoirs. The method is simple and eliminates the need for hydraulic pumps and plumbing. Alternatively, oil is supplied under pressure from an external pump and fed through oil lubrication channels.