ELID is a new technique that uses electrolysis to remove bond material. The application of this dressing technique during the course of a grinding process allows chips and debris to be removed easily and allows grindability to be maintained over a long period of time. Various applications of ELID grinding have been developed. With ELID dressing, it was possible to realize mirror grinding with various types of systems using existing machine tools such as [Ohmori and Itoh 1998, Ohmori and Li 2000a]:

• Surface grinders

• Rotary surface grinders

• Turning centers

• Infeed grinders

• Lap grinding machines

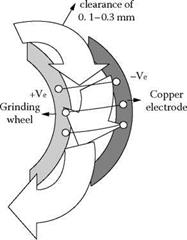

The ELID system consists of a negative electrode, a brush, a power supply, a metal-bonded wheel, and an electrolytic grinding fluid (Figure 14.10).

|

Grinding fluid in a small

FIGURE 14.10 The phenomenon of electrolysis in-between grinding wheel and a copper electrode. |

The wheel is made the anode of the power supply through the application of a brush smoothly contacting the surface. The cathode is placed in proximity to the wheel surface. The power supply transforms an alternating current into direct current as necessary for electrolysis. Generally, ELID must be applied to a wheel, which has been trued to run concentric to the spindle axis. The shape of the wheel is profiled to the required geometry and dull abrasives are fractured. Before commencement of grinding it is necessary to perform a predressing operation because it is necessary to have diamond grains exposed above the level of the bond. Truing of the grinding wheel is, therefore, required for the following reasons [Ohmori and Itoh 1998, Ohmori and Li 2000a]:

• The wheel must be concentric to the spindle axis.

• The wheel profile must have the correct geometry.

• Dull abrasives need to be fractured.

After truing, an ELID predressing operation on the diamond wheel is necessary to

• Expose diamond grains above the bond level (sharpening)

• Provide chip clearance

Diamond grains protrude from the wheel surface after predressing of the wheel.

The ELID process is performed in the following three steps [Marinescu and Ohmori 1999]:

1. Precision truing of the grinding wheel carried out by the electrodischarge truing technique

2. Predressing of the grinding wheel by electrolysis

3. Grinding with ELID

The cast-iron bond material of the grinding wheel is electrically conductive. Power is supplied to the metal bond through a brush that contacts the wheel. A copper electrode forms the cathode and a current is provided through the electrolyte in the gap between the anode and the cathode.

Electrolysis occurs at the gap between the metal bond and the electrode. The cast iron is ionized into Fe2+ [Ohmori and Li 2000b]:

Fe => Fe2++2e — Fe2+ => Fe3++ e-

H2O => H++OHFe2++

2OH- => Fe(OH)2

Fe3++3OH- => Fe(OH)3 2Fe(OH)3 => Fe2O3+3H2O

The above chemical reactions show that the ionized Fe forms hydroxides, and these substances change into oxides such as Fe2O3, which form an insulating layer. The electroconductivity of the wheel surface is reduced due to the growth of the insulating layer. After the oxide layer is formed and predressing is completed, ELID grinding can be performed [Ohmori and Itoh 1998].

Due to grinding, the oxide layer is removed when the wheel touches the workpiece. The thickness of the oxide layer is decreased and electroconductivity increases again. The metal bond is removed by electrolysis and transformed into a further oxide layer. The result is new sharp edges protruding from the surface of the wheel. This means that electrolytic in-process dressing is performed at the same time as grinding. The mechanism of ELID is shown in Figure 14.11.