The enhanced strength and toughness of ZTA ceramics have made these materials more widely applicable and more productive than plain ceramics and cermets for machining steels and cast irons. ZTA ceramics can be used as cutting tool inserts for metal cutting applications [Sornakumar and Gopalakrishnan 1995].

Cutting inserts are made by sintering followed by grinding and lapping. During the sintering process, ceramics are subject to volumetric shrinkage and as a result cannot meet the requirements for form and size accuracy without further machining. To meet these demands, machining by grinding, lapping, honing, or polishing with diamonds is necessary.

The performance of ZTA cutting inserts is strongly influenced by the grinding process. The active faces of the inserts should be smooth, without cracks, and the cutting edges should be free of chips. ELID grinding can provide a solution to these requirements such that dimensional accuracy and surface quality are achieved and even surpassed with a considerable increase in productivity [Marinescu and Ohmori 1999, Ohmori and Li 2000a].

The ELID grinding technique was recently developed in Japan and there is an increased tendency to apply it for grinding hard and brittle materials [Bandyopadhyay 1996, Ohmori and Li 2000a]. However, there are still insufficiently explored areas that make industrialists hesitant in adopting the method. Very little experimentation on ELID grinding has been conducted in the United States until very recently. The need for further practical information provides the motivation for further research.

14.2.4 G rinding of Ceramics

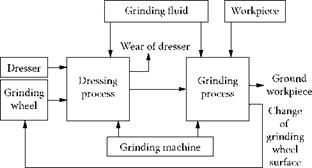

The characteristics of grinding advanced ceramics are very different from the ones for metals and research is still ongoing for a more comprehensive understanding and a better control of grinding parameters. Figure 14.1 presents the factors affecting the grinding process [Marinescu and Ohmori 1999].

|

|

Due to the fact that ceramics are brittle and have high hardness they are best ground using diamondgrinding wheels [Marinescu et al. 2001].