|

The last group of alloys is the stainless steels defined as steels containing more than 10% chromium. These are designed first and foremost to resist oxidation where they are used in the food, medical, petroleum, and chemical industries. In addition, some precipitation-hardened stainless steels are

|

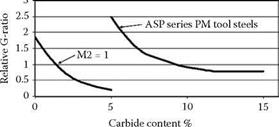

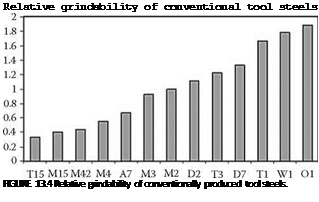

Comparison of G-ratio values grinding conventional and PM tool steels as a function of carbide content

FIGURE 13.5 Comparison of the grindability of tool steels, based on carbide content, made by conventional and powder-metal methods. |

designed to withstand high temperatures, bringing them into the lower end of the range of heat — resistant alloys used in the aerospace industries. They are characterized by producing long chips when ground and a tendency to cause loading. They also will work-harden producing high grinding forces and wheel wear. Currently most applications are ground using the more advanced ceramic such as SG — or TG-type grains or regular alox grains in continuous dress creep feed (CDCF) grinding.

Precipitation-hardened steels lead into the final and most difficult of material groups to grind in the high-production manufacturing arena.