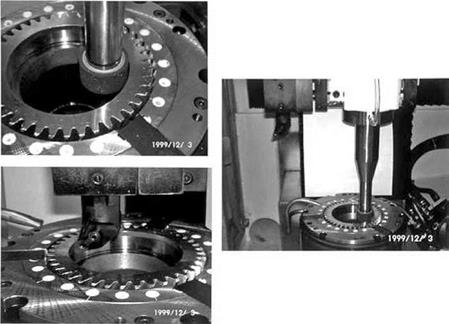

Hard turning can remove stock much faster and with lower forces than regular grinding processes but it cannot hold quite the tolerances and finishes of grinding. However, when combined in a single machine with a single chucking the two processes can enhance each other. The photographs in Figure 12.4 show an operation to process two inner diameters and the faces of a hardened steel transmission gear component. The process was originally envisioned as being processed entirely by a single grinding wheel with an estimated cycle time of 4 min. The critical surfaces were the inner diameters. The problem, however, was the grinding of the top face due to quill deflection resulting in a cycle time of 10 min. However, the addition of a turning bar for hard turning the top face reduced the cycle time to 3 min to exceed end-user expectations while still maintaining very acceptable quality.

|

FIGURE 12.4 Multitasking machine for grinding and hard-turning. (Courtesy of Campbell Grinders. With permission.) |

Close attention must be paid to the entire cost of a given manufacturing process. On very few occasions, the abrasive cost alone for a given operation governs the processing route. Continual advances in machine tool, wheel, and coolant technology, together with ever-greater demands for productivity, quality, and environmental considerations, demand that the manufacturing engineer review all options available each time an opportunity for new equipment arises. Careful consideration should be given to emerging technologies, global sourcing (if backed up with adequate local technical support), and fundamental university and corporate research.