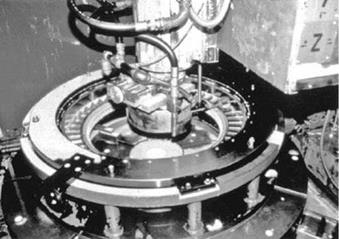

The application illustrated in Figure 12.1 is the internal grinding of large aeroengine shroud assemblies for aircraft engines. Traditionally, the part was ground using seeded gel (SG) abrasive, but the SG process was replaced by a vitrified CBN wheel that reduced grind cycle time by 50%. The greatest time saving was achieved by the elimination of the need to dress several times for each component ground. Relevant costs are given in Table 12.2.

Cost items 1 to 4 are tooling costs and illustrate that the switch to CBN abrasive created a negative impact on grinding costs of $12.11. However, the increased productivity, items 5 to 8, had a positive impact on labor cost alone of $179.44. Also, the quality improvement as a result of the very low wheel-wear rate using the superabrasive yielded an even greater cost saving of $399 by

|

TABLE 12.1 Total Manufacturing Cost Calculation Worksheet

|

|

TABLE 12.2 Cost Calculation for Internal Profile Grinding of Aeroengine Shroud Assembly

|

|

|

the elimination of scrap. Finally, there was also a modest environmental benefit of $0.36 in terms of reduced coolant-disposal costs. Converting from a conventional wheel with a G-ratio of 1 to a CBN wheel with a G-ratio of 1,000 effectively halved the amount of swarf in the coolant stream. Furthermore, the filtered swarf was much cleaner and, therefore, easier to recycle.

In summary, a change of process from traditional wisdom considering abrasive cost alone would have had a negative impact of $18.74/part. In fact, the change of process reduced total manufacturing cost by $569.47/part.