The determination of microgeometrical quantities on a moving workpiece by using contacting sensor systems is a challenging task. A permanent contact of any stylus to the surface is not possible because the dynamic demands are much too high. Only intermittent contacts can be used to generate a signal, which should be proportional to the roughness. Salje [1979] introduced a sensor based on a damped mass spring element. The surface of the fast-moving workpiece stimulates selfoscillations of the sensing element, which are correlated to the roughness. Also, rotating roughness sensors for OD grinding have been tested, but in the end, because of limitations including wear and speed, the idea of contacting the surface for roughness measurement has not led to industrial success [Karpuschewski 2001].

|

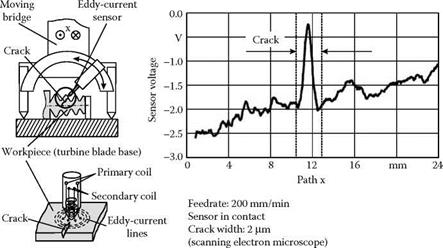

Filter: 10 Hz FIGURE 11.19 Eddy-current crack detection after surface grinding of turbine blades. |