At present, the most common type of cooling lubricant nozzle is the free jet nozzle aimed at flooding the entire contact zone. Being rather simple in design, this nozzle type is oriented in the tangential direction to the grinding wheel. In addition, the nozzle outlet should be positioned very close to contact zone. By varying the volume flow, the flow pressure, and the outlet cross-sectional area, the flow velocity can be matched to the peripheral velocity of the grinding wheel, being a prerequisite for maximizing the volume flow through the contact zone. However, it is only the minor part of the lubricant used that enters the contact zone since the maximum flow through the contact zone is geometrically limited by the pore space of the grinding wheel or the grinding layer. The geometry of the free jet nozzle is independent from the wheel profile or its dimensions, which makes this nozzle type relatively flexible in application. A tangential nozzle with a small width is referred to as a point nozzle, whereas the combination of several point nozzles is called a needle or multipoint nozzle [Heinzel 1999].

10.9.2 The Shoe Nozzle

An alternative nozzle design combining elements for deflecting the rotating air cushion with a highly effective distribution of the cooling lubricant to the contact zone is the so-called shoe nozzle. This nozzle type fits exactly to the wheel profile and encloses the grinding wheel on three sides.

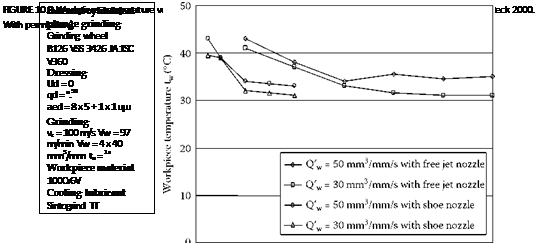

The rotating air cushion is deflected at the nozzle inlet allowing the complete wetting of the wheel surface with lubricant at the inner chamber of the shoe nozzle. The rotation of the grinding wheel itself accelerates the fluid to circumferential velocity. The total amount of cooling lubricant supplied can be limited to the volume necessary to fill the whole pore space of the wheel surface because a further supply shows an insignificant effect on the work result (Figure 10.3). The nozzle geometry is determined by the grinding wheel profile and an adjustment to a changing wheel diameter is required; hence, there is only a limited flexibility in the application of those nozzles. Several investigations prove the capability of this nozzle form to reduce the wheel wear as well as the thermal degradation of the boundary layer with a less required flow rate of the lubricant [Tawakoli 1990, Heinzel 1999, Beck 2000].