10.4.1 Introduction

In many cases, mineral oils are used as the base material for cooling lubricants. Mineral oil bases consist of hydrocarbons with mostly paraffinic, naphthenic, or aromatic structures. Depending on the fraction of the paraffins, naphthenes, and condiments, a distinction can be made between paraffin-based, naphthene-based, and mixed base oils [Mang 1983, Moller and Boor 1986]. The main advantages of paraffinic base oils in cooling lubricants are good viscosity-temperature behavior, high aging resistance, small affinity to evaporation, high flashpoint, and low toxicity. In contrast to paraffin-based mineral oils, the advantages of nephthene-based oils are their good resistance to cold, better thermal stability, higher moistening capacity, and active agent solubility [Moller and Boor 1986, Pfeiffer et al. 1993]. Extracted and deparaffined solvent-raffinates or hydrocrack oils are gaining even more importance due to a lower condiment ratio, less mist generation, and high resistance to aging [Konig et al. 1993, Kassack 1994]. Also, synthetically produced poly-alfa-olefins, polyglycols, and esters are increasingly used, which, in contrast to mineral oils, have higher viscosity indices, a lower affinity to evaporation, longer service life as a result of high thermal stability, and/or resistance to oxidation and high human compatibility. Additionally, esters have especially good lubricating characteristics [Mang 1983, Konig et al. 1993, Pfeiffer 1993, Kassack 1994]. General values of the kinematic viscosity of cutting and grinding oils are in the range of v = 2.0 to 45 mm2/s at 40°C [Mang 1983].

|

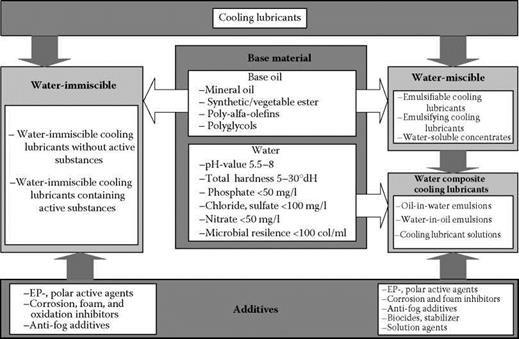

FIGURE 10.1 Classification and composition of cooling lubricants. (From Brucher 1996. With permission.) |