|

||

|

||

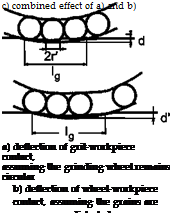

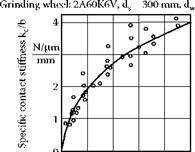

A characteristic feature of grinding dynamics is that the elastic deformation of the grinding wheel is too large to be neglected and, furthermore, it has a significant influence on the process stability. The contact stiffness of the grinding wheel is defined as the relationship between the normal compressive force Fn and the elastic deformation of the grinding wheel S induced at the contact zone. Some models have been proposed for theoretically calculating the elastic deformation of grinding wheels by applying the Hertzian elastic contact theorem (Figure 8.9 and Figure 8.10)

|

|

|

|

|

[Brown et al. 1971, Inasaki 1975]. According to those analyses, it is suggested that the deformation 8 is given by following equation:

![]() 8 = F p

8 = F p

n

where 0< p < 1.

Therefore, the contact stiffness obtained through differentiating Equation 8.8

к =^n (8.9)

c d8

has a nonlinear characteristic of the hard-spring type. By combining Equations 8.3 and 8.9, the contact stiffness can be expressed as a function of the grinding set-up parameters. For example, the increase of the speed ratio vjvs and the depth of cut results in an increase of the contact stiffness.

The contact stiffness has also been experimentally investigated [Inasaki 1977a, Younis 1972]. Of course, an increase of grinding wheel hardness corresponds to an increase of the contact stiffness.